Sign in

Create new account and sign-in.

2FA protect your account

Add to cart

Find your parts and add to cart.

Pay

Pay via Cards or Paypal.

Contact us for more currency support.

Get Delivered

We mange delivery

AIRPARTS CONDITION CODES FOR NEW AND NON-NEW PARTS

NE – NEW – FACTORY NEW PARTS WITH FULL TRACEABILITY

This is to categorize a brand new, unused component part or any material produced in conformity with approved data by an original equipment manufacturer (OEM), authorized manufacturer with Parts Manufacturing Authorization (PMA), or other authorized source and is accompanied by a manufacturer’s material certification which can include an FAA 8130-3 or any other approved manufacturer’s certificate of conformance, provided at the time of sale and has no cycles or operating time on the part. Generally, this part comes in an unopened or sealed OEM container or packaging. These parts are the highest cost parts in the aviation supply chain.

RB – REBUILT – PARTS IN NEAR-NEW CONDITION REBUILT BY OEM OR PMA

Used components, parts, or rotables which have been rebuild to exacting original tolerances by either the OEM or an approved PMA. These items are usually received by the OEM or PMA as cores or exchanges then completely rebuilt by either the OEM or an approved PMA and are considered to be like new items. These items will include an FAA 8130-3 form and if a PMA rebuilds the item, it will also include a PMA number as reference on the 8130-3 form. These parts make excellent substitutes for new parts and will generally cost less than new parts.

OH – OVERHAULED – PARTS IN EXCELLENT CONDITION AND OVERHAULED BY OEM OR FAA APPROVED PART 145 CERTIFIED FACILITY

Used components, parts, or rotables which have been overhauled by the OEM, OEM approved third party, or an FAA Part 145 repair station using methods, techniques, and practices acceptable to the FAA and following the OEM’s overhaul and rebuilding procedures. These items have been disassembled, checked, cleaned, inspected, repaired, and rebuilt to meet OEM original performance and tolerances. These items were then tested in accordance with OEM and FAA approved technical data and standards acceptable to the FAA. These items will generally include an FAA 8130-3 form. These items cost less than New or Rebuilt parts and should be trusted to provide very similar performance to new or rebuilt parts.

NS – NEW SURPLUS

New, unused component part or any material produced in conformity with approved data by an original equipment manufacturer (OEM), authorized manufacturer with Parts Manufacturing Authorization (PMA), or other authorized source which is not accompanied by a manufacturer’s material certification which can include an FAA 8130-3 or any other approved manufacturer’s certificate of conformance. These types of items generally are purchased from the OEM, an owner or operator (commercial or non-commercial), a certified repair station, a maintenance facility, distributor, or through an insurance company and do not include documentation but will generally include traceability. Sellers may also provide traceability documents along with the NS items. These items are usually sealed in original packaging or come in packaging and are unused new items.

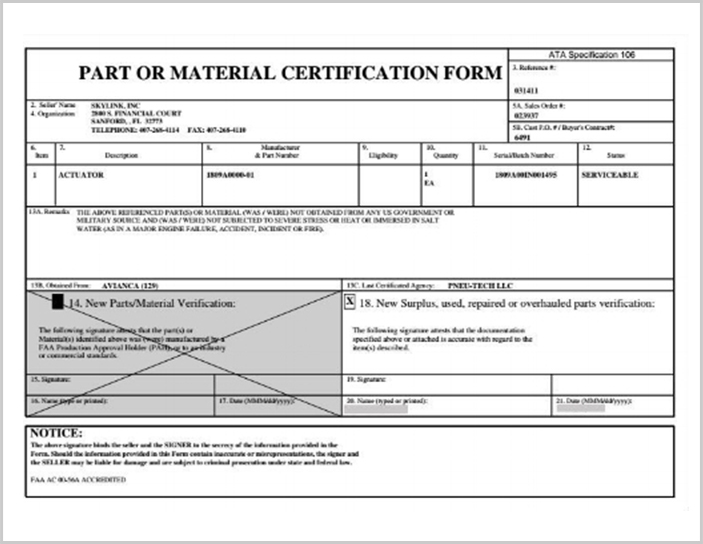

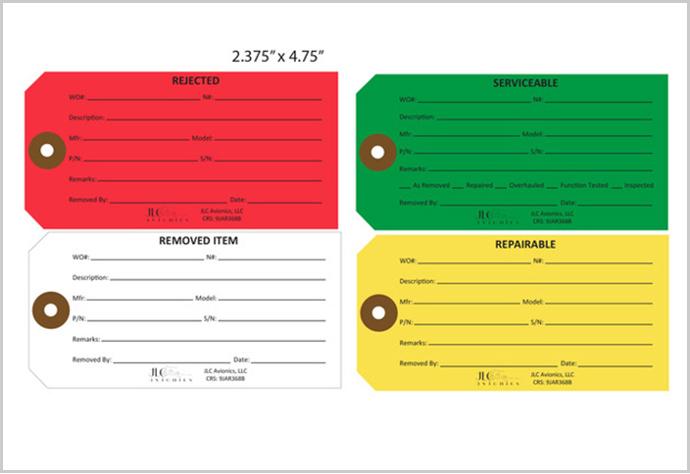

SV – SERVICEABLE

Items falling in this category of condition include used components, parts, or rotables which have been removed from operation, traceable to its original last known use source, and are approved for installation and use. Any item in SV condition meets the manufacturer’s performance and operational specifications and can be returned to service. The initial inspection to determine if this item meets manufacturer’s specification is generally performed by the mechanic removing the item from the airframe or another FAA licensed individual qualified to make the determination. Once the determination is made, a release certificate or tag is attached to the item indicating the item is serviceable. This tag also includes the source of the part, date of removal, date of inspection, and any other pertinent information related to the item. Return to service would require an FAA licensed A&P mechanic to inspect the item and agree to sign off on the items installation and return to service. These items make excellent economical solutions if you need a part for short term or if you are trying to save some money. AirParts does not make any determination on the condition of SV parts. Sellers on the AirParts platform will make their certification on the SV condition through their listing of the part.

AR – AS REMOVED

Any components, parts, or rotables which do not have an FAA 8130-3, Certificate of Conformity, or any yellow, red, or white tag and an item that has been removed from an aircraft and has not been tested or inspected. The item may be good but would require additional testing or inspection and possible repair, overhaul, or modification to legally reinstall the item on an aircraft. Generally, these parts will have a tag that will provide a trace back to the source, date of removal, and other information. Depending on the part, an FAA licensed A&P may perform the inspection and rebuild, repair, or modification of the AR part. Please note, if purchasing AR parts, the buyer is responsible for making sure the part is in compliance with FAA airworthiness requirements as supported by the FARs. The buyer of an AR part is responsible for converting an AR part to usable by compliance with FAR Part 21 of 14 CFR or any other applicable standards by obtaining all required FAA repairs, inspections, modifications, or overhauls prior to use. There are no guarantees that AR parts will be usable and AirParts makes no guarantee of this nature. You can send a question to your AirParts seller for more information on the AR part you are considering to purchase through the message center. AR parts can also be used as core replacements if you need a part to return to a vendor as a core should you not have a core to fulfill the core return requirement.

IN – INSPECTED

Any components, parts, or rotables which has been inspected to determine conformity with acceptable and available FAA, manufacturer, or PMA data. Inspections can be done by visual or through a testing procedure acceptable to the Administrator. This category of part is tested and inspected and found to not have any defects or faults during and after the inspection. All traceability and testing paperwork is generally provided with parts in the IN category.

RP – REPAIRED

Any components, parts, or rotables which has been restored or repaired to serviceable condition status through conformity of procedure and data acceptable to the Administrator, the manufacturer, and/or the PMA.

MO – MODIFIED

Any components, parts, or rotables which have been altered or modified in accordance with and in conformity with approved data, approved by the Administrator, manufacturer or PMA

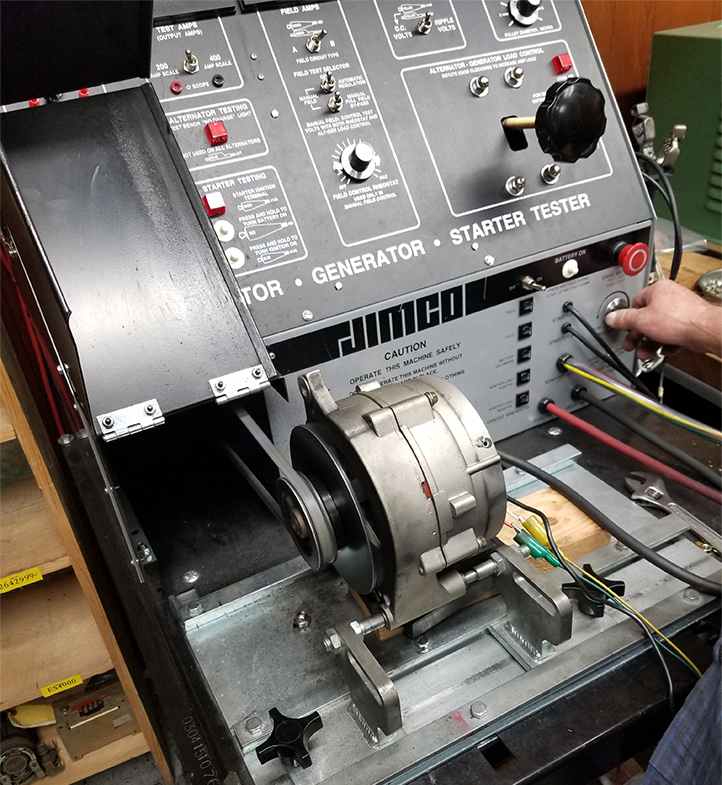

TST – TESTED

Any components, parts, or rotables which have been inspected, tested, and examined through test procedures approved by the FAA, the manufacturer, or the PMA and for which the test procedures establish conformity to operating specifications.

Shop in 60+ currencies

Secure payments

Parts Certification

FAA Quality Control

Track your package

24/7 Customer Service